BIW Solutions

Automation Products

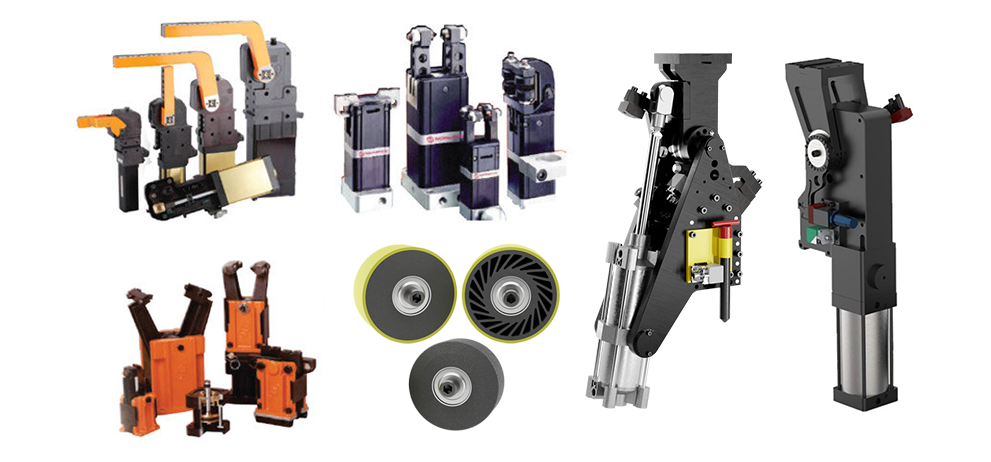

Tech Rim Standards line of high end, heavy duty automation products covers the realm of welding, robotic and assembly manufacturing.

With over 40 years of global – in plant, program usage for the automotive, packaging, glass, aerospace, and medical worlds –

These are built to last and are readily available. Our comprehensive line includes:

- Power Clamps

- Pivot Units

- Conveyor Rollers

Contact us for more information or download what you need.

EC Power Clamps

Power clamps are robust, automated clamping devices used in tooling systems to securely hold workpieces in place during machining, welding, or assembly operations.

They deliver consistent clamping force, improve cycle times, and enhance safety by reducing manual intervention in high-precision manufacturing environments.

Cylinder Sizes: 40, 50, 63, and 90.

The EC Series power clamps at Tech Rim Standards feature a toggle lock to incorporate a "before center" toggle mechanism. As such, they generate higher clamping forces with this locking ability.

Additonally, with a built-in "stroke-to-go" feature, this power clamp delivers the highest industry standard for repeatability.

Automation Rollers

Automation rollers are critical components in material handling systems, enabling smooth, efficient, and controlled movement of goods across production lines.

Designed for durability and precision, they help streamline workflows, reduce manual handling, and support high-throughput operations in automated environments.

There are three types of rollers that are best for specific uses;

- RR42 Rollflex Cushion Roller (Tuff Skin-Tender Heart)

- CR42 Cushion Finned Roller (The Soft Touch)

- SR42 Rollflex Cushion Roller (The Heavy Mover)

EC Power Clamps

Power clamps are robust, automated clamping devices used in tooling systems to securely hold workpieces in place during machining, welding, or assembly operations.

They deliver consistent clamping force, improve cycle times, and enhance safety by reducing manual intervention in high-precision manufacturing environments.

Cylinder Sizes: 40, 50, 63, and 90.

The EC Series power clamps at Tech Rim Standards feature a toggle lock to incorporate a "before center" toggle mechanism. As such, they generate higher clamping forces with this locking ability.

Additonally, with a built-in "stroke-to-go" feature, this power clamp delivers the highest industry standard for repeatability.

GL/GH Grippers

Grippers are essential components of tooling systems, designed to securely grasp, hold, and manipulate parts during automated or manual operations.

They enhance precision, efficiency, and safety by ensuring consistent handling of materials in manufacturing, assembly, and robotic applications.

Between the GL and GH Series of grippers at Tech Rim Standards, there are five cylinder sizes available.

Cylinder Sizes: 16, 28, 32, 35, and 40.

The GL Series of grippers feature a modular 360° swivel-head adjustment and work with flange and orbital rod mounts.

The GH Series of grippers comes in three sizes; mini, standard, and heavy-duty. Between them there are 50 different gripper head combinations, and feature 2/4 point gripping.

| Model Number | Bore Size | Dimensions | Weight |

|---|---|---|---|

| GL400 | 1.50 inches (Ø 38 mm) | 1.69 inches (43 mm) x 1.88 inches (48 mm) | 2.20 lbs (.998 kg) |

| GL500 | 2.00 inches (Ø 51 mm) | 2.25 inches (57 mm) x 2.50 inches (63 mm) | 4.40 lbs (1.996 kg) |

| GL700 | 2.75 inches (Ø 70 mm) | 3.00 inches (76 mm) x 3.25 inches (82 mm) | 9.90 lbs (4.491 kg) |

Automation Rollers

Automation rollers are critical components in material handling systems, enabling smooth, efficient, and controlled movement of goods across production lines.

Designed for durability and precision, they help streamline workflows, reduce manual handling, and support high-throughput operations in automated environments.

There are three types of rollers that are best for specific uses;

- RR42 Rollflex Cushion Roller (Tuff Skin-Tender Heart)

- CR42 Cushion Finned Roller (The Soft Touch)

- SR42 Rollflex Cushion Roller (The Heavy Mover)